In 2023, as the Team Captain for Aerothon, I had the privilege of leading a talented group of individuals in

designing and building a cutting-edge 2 kg quadrotor UAV. Our mission was to create a drone capable of

achieving a minimum 10-minute flight time while executing advanced tasks such as payload drop and object

detection and classification. The challenge demanded not only innovation in design but also efficiency in

execution, pushing us to think creatively and strategically.

Our X-frame design was a deliberate choice, prioritizing stability and agility to handle the multiple

onboard components. This structural decision enabled us to achieve remarkable speeds of up to 18.5 m/s,

allowing us to complete the entire mission in half the allocated time. This efficiency became a significant

competitive advantage, enhancing our performance.

A. Structural Design and Performance

To meet the demanding performance requirements, we opted for a wooden UAV frame—an unconventional but

strategic decision. While wood is not traditionally used in UAV manufacturing due to its low strength, we

innovated by employing Medium Density Fiber (MDF) board. Using laser cutting technology, we could fabricate

the UAV in under 30 minutes using easily available materials.

To address the strength limitations of wood, we designed a jigsaw-style interlocking structure, creating a

frame capable of withstanding a 15-foot free fall. This modular design ensured:

High reproducibility

Material availability

Ease of assembly

Our creative material choice reduced fabrication time and simplified repairs,

making the UAV highly efficient and field-ready.

B. Telemetry and Computing Efficiency

To optimize the UAV's performance, we implemented a robust telemetry system that allowed us to run complex

computing tasks on the ground with minimal latency. By offloading the processing tasks, we eliminated the

need for an onboard computing system, saving valuable weight. This streamlined approach reduced power

consumption and improved the drone's flight efficiency.

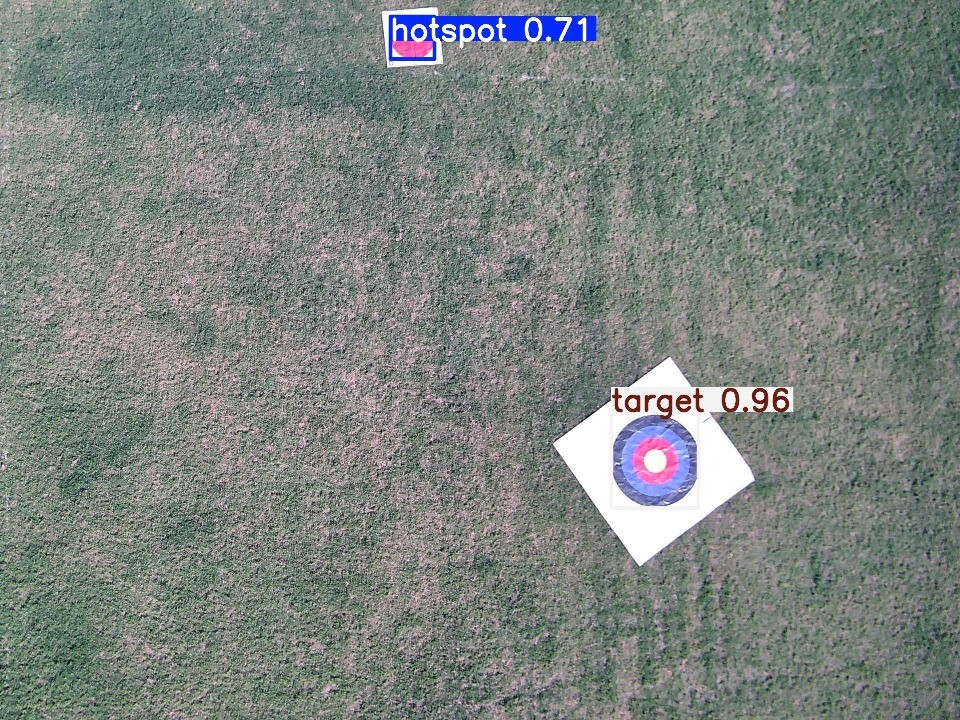

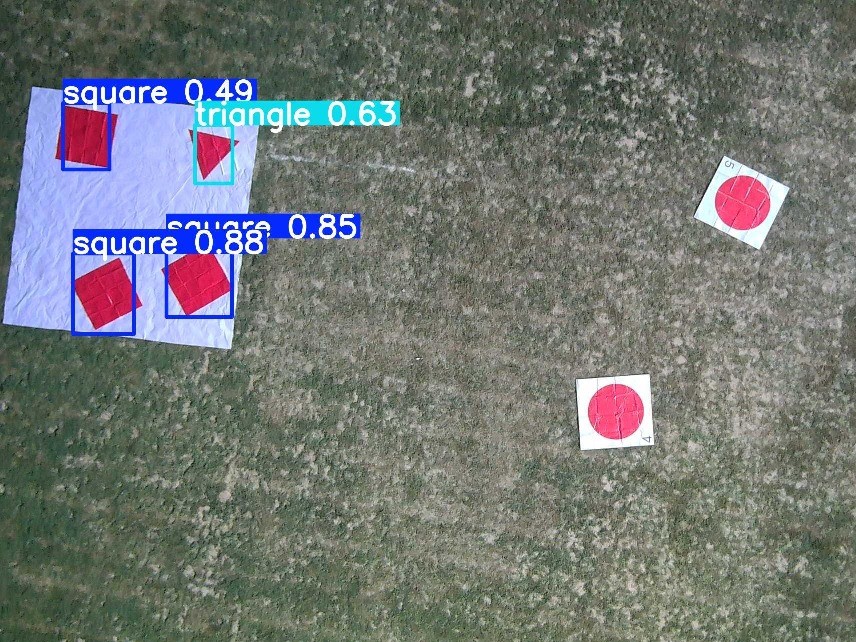

Our UAV was designed to autonomously detect and classify objects while executing precise payload drops. The

object detection system employed advanced computer vision algorithms, enabling accurate target

identification.

For the payload delivery mechanism, we developed a reliable and lightweight drop system, ensuring consistent

and precise deployment. The seamless integration of these capabilities allowed us to meet the competition's

technical requirements effectively.

Throughout the 7-month development journey, our team faced several challenges:

Material strength limitations: The use of MDF required rigorous testing to

achieve structural integrity.

Skepticism around wooden UAVs: The unconventional choice faced initial doubts but

ultimately proved effective through successful stress testing.

Weight and stability optimization: Balancing the weight-to-performance ratio was

a constant challenge, which we addressed by optimizing the frame and telemetry system.

Through determination, innovative problem-solving, and iterative design improvements, we successfully demonstrated the feasibility of a wooden UAV body, paving the way for future innovations in drone design.

The culmination of our efforts resulted in a UAV that showcased:

Exceptional speed and agility, completing the mission in half the allocated time.

Reliable payload delivery with precision accuracy.

Efficient object detection and classification capabilities.

Minimal fabrication time with easy-to-procure materials.

Our project marked a significant departure from conventional UAV designs, pioneering the use of wood in UAV fabrication. The groundbreaking achievement highlighted our team's creativity, ingenuity, and resilience, setting a benchmark for future UAV innovations.

Aerothon 2023 was more than a competition—it was a testament to innovation through experimentation. By challenging traditional design norms, we demonstrated that unconventional materials and out-of-the-box thinking can yield exceptional results. This experience not only strengthened our technical expertise but also reinforced the importance of pushing boundaries in engineering and UAV development.